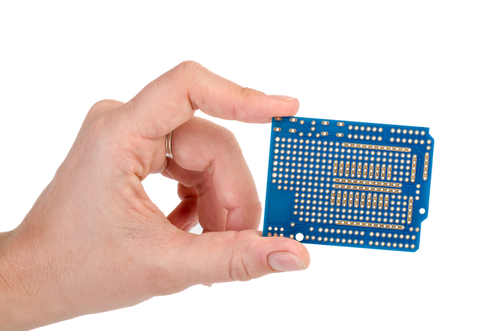

Lasting electronic designs require accurate and quality manufacturing at their root. Prototyping of PCBs is a crucial stage of electronics project development and allows engineers to design their circuit boards and test the outcome on small-scale runs; often taking multiple runs to perfect their designs.

The main intention of prototyping is to not only test the concept and functionality of the design, but also perfect and grow it stage by stage, limiting final fabrication failure as much as possible. This should save unnecessary additional costs and extended project times.

Speed and flexibility are often the main focus of this development stage facilitating rapid testing of ideas and amendments where appropriate. Companies desire fast turnaround Prototype PCBs as the quicker the designs can be verified, the quicker products get to market optimising sales revenue potential and profitability.

Types of Prototypes:

- Limited function: Test out each intended final function of a circuit board within single function boards.

- Functional Concept: proves the concept of the circuit built up without full capabilities.

- Working prototype: Fully integrated functions which will be refined through further runs.

- Fully Functioning Prototype: Combines all aspects of functionality intended for the finalised circuit design as well as the adapted characteristics that have been developed through the runs. This prototype will reflect the final production board.

Main Benefits

✓

-

- Helps to reduce the time from idea > market

✓

-

- Allows you to test design in small quantities before primary large production

✓

-

- Ensures manufacturability

✓

-

- Ensures quality

✓

-

- Ensures functionality

✓

-

- Cost effective for multi-layer or high-density boards

✓

-

- Reduces costly reworks

✓

-

- Fine-tuned, validated designs

✓

- Eliminate failures early

How PCB Train Can Help ?

It’s a common misconception that good value and low volume pcb fabrication do not go together. Here at PCB Train although we recognise there are associated costs we specialise in providing a low cost fast turnaround PCB prototype service. What’s more, by using us for your PCB assembly order you can utilise our free components list through which clients can take advantage of free common components for their boards further reducing costs.

Use our online system to generate a quote for your prototype and small batch PCBs

Leave a Reply