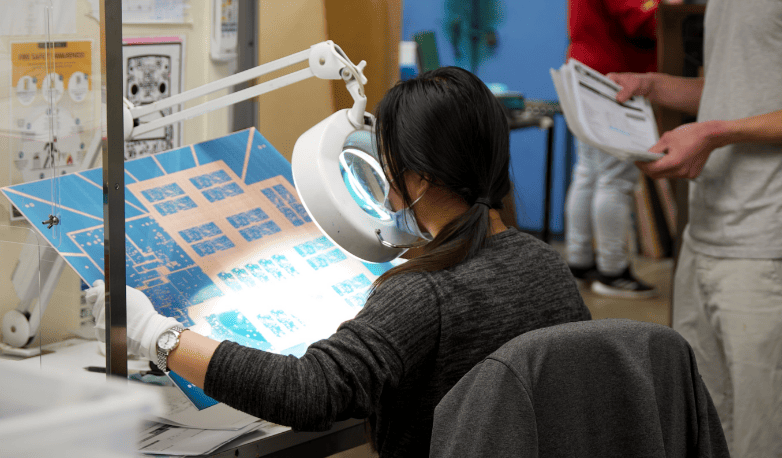

Due to the complex technical challenges of different orders, most PCB manufacturers only allow one PCB design to be processed per production sheet. Our production process is a little different. Due to a half-century of industry experience, we have mastered the techniques of manufacturing different PCB designs on the same production sheet in order to lower production costs significantly. Use our online PCB quote service to find out how much you could save on your order.

PCB Train’s unique methods of production are extremely efficient and can get your PCB board to you when you need it most. Our PCB fabrication process allows for the creation of PCBs with up to 12 layers. These are available in a range of solder masking options, as well as various materials and colours.

Follow the links for useful tips on PCB design for manufacture and more information about PCB assembly.

Place your bare PCB order below.

Get Started

PCB Train express, 24 hours

1 to 12 layers PCBs

Gold or silver finishes

100% electrically tested

Choice of materials FR4, Polyimide, AlClad

Choice of thickness, legend & resist colours