With the world’s reliance on electronics increasing, printed circuit boards are becoming more sophisticated than ever. One example of this is SMD PCBs, which use advanced surface mount technology (SMT) to power everything from consumer electronics to large pieces of machinery.

Read on as we explore the most common uses of SMD PCBs and how they differ from more traditional printed circuit boards.

What are SMD PCBs?

A surface mount device (SMD) is an electronic component that mounts directly onto the surface of a printed circuit board. Some examples of SMD components include resistors, chip carriers, transistors and capacitors, all of which feature on most modern PCBs.

SMD PCBs are printed circuit boards that accommodate any number of SMD components. They are generally smaller than those assembled via through-hole technology (THT) and can reduce production costs significantly.

Surface mount technology vs. through-hole technology

Since becoming popular in the 1980s, surface mount technology has overtaken through-hole technology as the predominant method of PCB assembly.

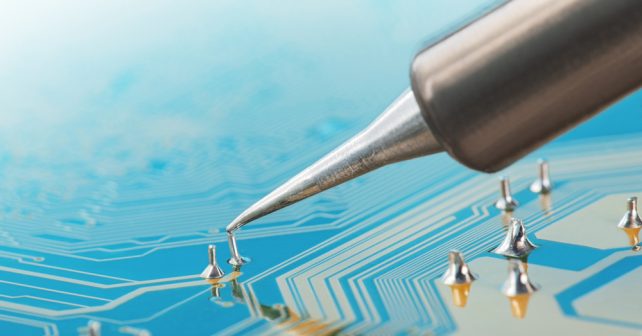

Where THT requires the assembler to thread component leads into holes drilled into the PCB, SMT allows them to solder components straight onto the surface. These days, automated machines carry out surface mount soldering tasks, but some people still like to do this by hand.

Compared to THT, SMT is generally less expensive, more reliable, and can incorporate more components in a smaller design. However, through-hole assembly still has some advantages, such as greater connection strength and high immunity to stress. It’s therefore not uncommon for experts to use a mix of THT and SMT in their PCB designs.

Common uses of surface mount devices

SMD PCBs, like any other form of printed circuit board, are essential to a wide range of electronic products. They are responsible for the safe and efficient running of devices across many industries and have several useful applications. Here are some of the most common.

- Consumer electronics – As everyday electronics get smarter, it’s down to PCB manufacturers to create circuit boards that can fit into smaller spaces without losing functionality. SMD PCBs enable smartphones, smartwatches, TVs, tablets and consoles to perform effectively, giving businesses reliable products that keep their customers coming back for more.

- Medical devices – PCBs are used in many medical contexts, providing functionality to imaging systems, monitors and devices such as pacemakers. As these tools require accuracy, the PCBs they contain must be reliable. They should also feature high sanitation standards, particularly in the case of internal devices.

- Military applications – Like the medical sector, the military requires durable and accurate technology to help complete a range of life-or-death tasks. Several high-quality SMD PCBs are incorporated into military applications to achieve this goal and are responsible for the efficiency of communication equipment, threat-monitoring tools and missile detection systems the world over. PCBs also keep us safe domestically and are vital to many home security devices such as smoke detectors and door locks.

- LEDs – Energy-efficient and better quality than traditional lighting options, LEDs are visible everywhere, from residential settings to commercial storefronts. One of LED PCBs’ best qualities is that they help transfer heat away from the bulb, which they achieve by using materials such as aluminium. In addition to lighting applications, LEDs help light up computer screens and dashboard displays.

- Aerospace – As they are able to withstand harsh conditions, PCBs are the perfect choice for aerospace applications. These days, they are essential components in planes, satellites and even space shuttles, with sophisticated builds ensuring safety and functionality.

Surface mount PCB assembly at PCB Train

PCB Train uses high-specification SMD placement machines and multi-zone convection reflow or vapour phase ovens to create high-quality SMD PCBs.

To find out more about our PCB fabrication and assembly services, please get in touch with us directly. Already know what you want? Get a quick online quote today.

Leave a Reply