As you all know, we love supporting and encouraging engineering projects. Recently we’ve been in contact with Michael Mannering who showed interest in our ‘Low Cost SMD Lead-free Solder Paste Reflow’ experiment. Michael is trailing the experiment himself and has kindly given us an insight into how his project’s going…

Micheal Mannering’s Reflow Oven Experiment

Now let’s start out by saying I have been making original electronic circuits since I joined London Transport Executive, Research Laboratories, at Chiswick London about 40 years ago. I had an excellent mentor in John Ewins who taught me how to layout Veroboard strip board circuits with high-density component packing. This approach to modern electronics is sadly coming to an end as fewer and fewer active chips are produced with through hole mounting packages. So I thought that if I was going to use all these new surface mount chips in my retirement, I had better get to grips with soldering surface mount chips to PCB’s.

It soon becomes evident that to hand solder these very tiny SMD resistors, capacitors, and chips requires supervision and rock steady hands, something that gets rare with increasing age. So wh at’s the answer?

at’s the answer?

The strange thing about a PCB designed to use SMD components and reflow soldering techniques, is that as long as you can get the placement of the components fairly well aligned with the PCB component landing pads, the solder paste will hold the component in place. What’s more when the solder paste flows it pulls the components into place by surface tension. So Reflow soldering seems to be the way to go.

Whilst looking on the Internet for a possible reflow oven in the sub £100 price range, I started looking at the possibility of making my own reflow oven and came across Philip King’s blog about the suitability of an Argos £40 oven to achieve reflow soldering.

Philip King is the Managing Director of Newbury Electronics since 1981 and is enthusiastic about discovering new technologies and leading innovative projects in the electronics industry. I commented on his blog about how I was going to take the Argos oven into the realms of a temperature controlled reflow oven.

This has resulted in his team asking me to submit a blog about how I intend to modify this Argos oven and then once built show how it performs, with my homebrew controller. So let’s consider the hardware that I am going to use.

Philip King has taken the risk I did not want to take, which was buying an oven and testing it. I now know with some certainty that the Argos oven will get the temperature profiles I will need to solder these SMD components.

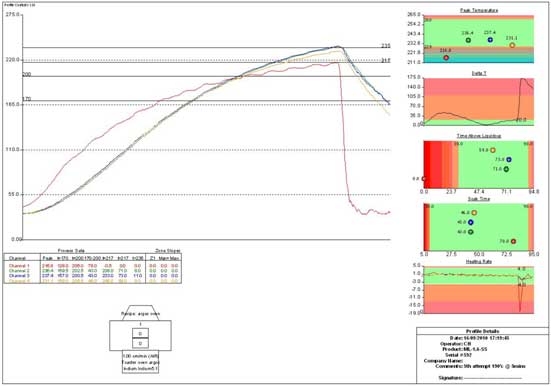

I need to measure the temperature of the oven near to the PCB and components being soldered, so some form of temperature measurement with heater control is required. The temperature measurement seems to be relatively easy to achieve with the Micro. I have sourced the Maxim 6675 IC, it is a Cold-Junction-Compensated K-Thermocouple to-Digital Converter (0°C to +1024°C) communicating with my Atmel control chip via a SPI interface. This is producing a stable reading and controlling a test heater quite well already.

The control of the ovens heater is g oing to be the critical part of the build; do I use a proportional-integral-derivative controller (PID controller) and or Pulse Width Modulation (PWM)?

oing to be the critical part of the build; do I use a proportional-integral-derivative controller (PID controller) and or Pulse Width Modulation (PWM)?

I have some leeway on this decision as I am going to control everything with an Atmel embedded controller, both these options can be programmed into the Atmel chip as software solutions.

So my first decision is to use a Solid State Relay (SSR) with an isolated 5-volt interface and integral zero crossing detector. A 20 Amp 250 VAC SSR is cheaply available on e-bay and 2 have been purchased.

I could just use this as an electrical thermostat in bang bang mode to control the oven heaters, but I think that the overshoot and hysteresis might cause problems. I also have a lot of old components, which may have absorbed moisture, so I may want a setting on the oven heaters to give the components a long, low-level dry out period. So my first iteration for the controller will be to feed the heaters (SSR) with a PWM signal that is a product of the error between required temperature and the actual temperature measured. I have this code and circuit working with the test heater. So it’s not so much PID or bang bang control of the heater, as something in between and easy to put into practice.

So now it is time to see if the hobby budget can stretch to the Argos Oven in the near future?

The modifications and test runs in producing a workable and reproducible flow soldered PCB will form the basis of the next blog. That is if Newbury Electronics/PCB Train can withstand this present blog. I am terrible about taking pictures but will post some, as soon as I can find the camera!

Hope to blog again soon.

Michael Mannering ( Aka Crusty)

A big thank you to Michael for providing us with an insight into his current project and we look forward to his next blog. If you’re currently undertaking a project that you think would be of interest to us then please contact marketing@pcbtrain.co.uk.

Leave a Reply